It is a good option to be used in indoor use. Accordingly, it is denser and stronger than exterior plywood. exterior grade plywood vs marine plywood.

Exterior Grade Plywood Vs Marine Plywood, Because of this, hardwood exterior plywood is a good choice when you need an exterior product. In this blog post, plyco will guide you through. Marine plywood has a smoother exterior than regular plywood.

Aamoda Plywood Commercial Plywood Dealer, Supplier From aamodaply.com

Aamoda Plywood Commercial Plywood Dealer, Supplier From aamodaply.com

The stuff is usually called wbp (water boiled proof). General exterior plywood is intended for indoor or outdoor application where resistance to weather/water is required. Marine plywood is of exterior grade.

Commercial plywood, no doubt, is compared to marine plywood.

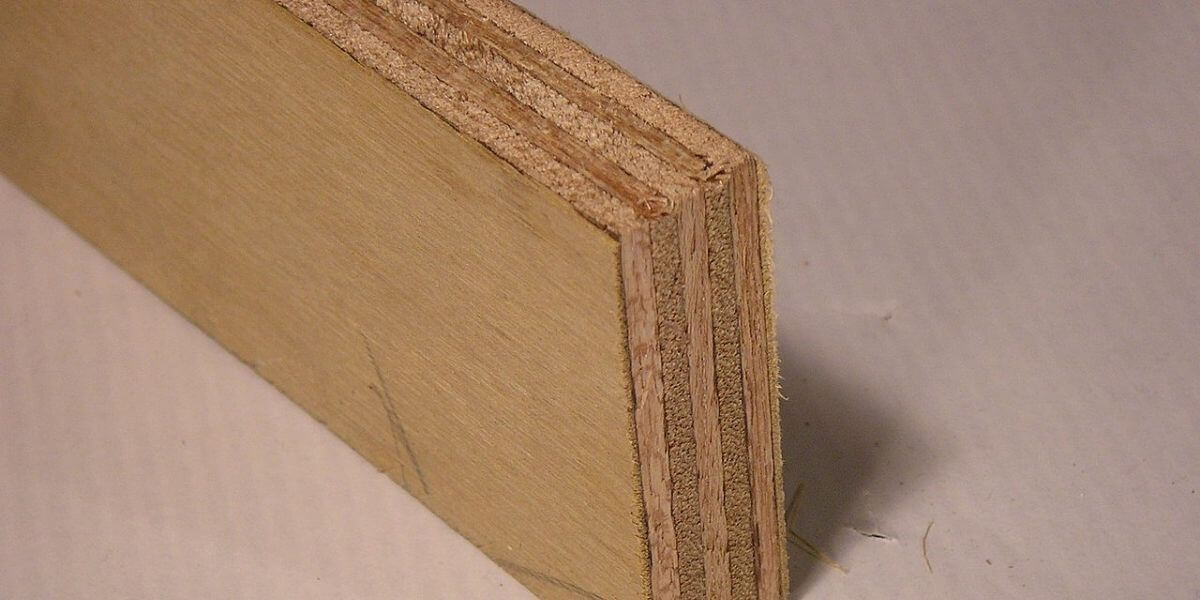

With marine grade, the lowest grade veneer that can be used is b, which means that there will be no voids on the surface or in the interior plies. The wbp plywood is one of the most durable plywood. Marine grade uses exterior adhesive. Accordingly, it is denser and stronger than exterior plywood. This entirely changes the look when that is the case. They�re both designed for exterior applications, but that doesn�t mean that exterior grade plywood and marine plywood are interchangeable.

Another Article :

Exterior plywood can come in reasonably thinner veneers to make them more affordable. The two plywood can differ in their thickness as well. Same is true of exterior grade. That said, medium density overlay plywood is by far the cheaper of the two when compared to marine plywood. A major difference our exterior plywood offers is that it comes in three different sheet sizes and this allows for greater flexibility during manufacturing. Marine Plywood Floor Paint Viewfloor.co.

This grade of plywood can feature knots up to 2.5 inches. Exterior plywood can come in reasonably thinner veneers to make them more affordable. Marine plywood can also be used in construction. There can be no voids or holes hidden on the inner layers of marine grade plywood. A 4×8 foot sheet of exterior graded plywood can cost around $10 a sheet. The Plyco Guide to Marine Plywood.

Because it has no voids, its strength is consistent across the wood and is. The difference between the two is that marine plywood is supposed to void free, just as john o points out. Marine plywood is of exterior grade. Both a and b grade may contain wood or synthetic patches. On the contrary, an exterior grade may have knots as big as 1”. Marine plywood vs exterior plywood what is the difference?.

Marine plywood is intended for use in boat building or other marine applications. They haven’t been repaired, and the flaws can be a little larger and more noticeable. Wbp plywood can be used as exterior grade plywood for construction. Marine grade has no special waterproofing in or on the wood, unless it has been added as a special feature. The difference between wbp and standard marine plywood is that marine plywood is guaranteed 100% void free, without any knotholes and cracks, while other wbp plywood may not be. How to Install EPDM Rubber Roof Easy DIY Fitting.

You can get the same performance from panels such as exterior ac in most cases. Its glue can be melamine or phenolic resin. Federal government but are a voluntary set of standards administered by the apa. Plywood grades are not regulated by the u.s. Marine grade has no natural decay resistance. Marine Ply vs BWP Marine and BWP Plywood Properties.

The difference between the two is that marine plywood is supposed to void free, just as john o points out. Commercial plywood, no doubt, is compared to marine plywood. Marine grade uses exterior adhesive. Marine plywood can be used for all the jobs which can be done by exterior plywood. A lot of exterior grade plywood is made using the same glue as marine grade plywood. 3/4 in. x 4 ft. x 8 ft. AB Marine Grade PressureTreated.

A grade phenolic resins are used for in. Commercial plywood is interior grade plywood. Exterior plywood is about ¾’’ thick and contains five plies of plywood with a fibreglass layer on its surface. The two plywood can differ in their thickness as well. Marine grade has no special waterproofing in or on the wood, unless it has been added as a special feature. Osb vs marine plywood Plans sailboat.

Marine grade plywood can be up to. There can be no voids or holes hidden on the inner layers of marine grade plywood. The grade of all plies of veneer is b or better. Marine plywood and exterior plywood are both very similar. A plywood cannot be considered marine grade without any of these factors. Buy 12mm Eucalyptus Veneer Plywood/Poplar Veneer Plywood.

Marine grade has no natural decay resistance. To be considered exterior grade or marine grade, plywood must be produced with wbp glue. The two plywood can differ in their thickness as well. What is the difference between marine plywood and exterior plywood? Plywood grades are not regulated by the u.s. S/Y Obelix Marine Grade vs. Exterior Grade Plywood.

They�re both designed for exterior applications, but that doesn�t mean that exterior grade plywood and marine plywood are interchangeable. The edges tend to cut and sand cleaner than the standard plywood. Exterior plywood can come in reasonably thinner veneers to make them more affordable. The difference between wbp and standard marine plywood is that marine plywood is guaranteed 100% void free, without any knotholes and cracks, while other wbp plywood may not be. Marine grade has no special waterproofing in or on the wood, unless it has been added as a special feature. Interior vs. Exterior Grade Plywood The Laser Co.

You definitely do not want to use anything as nasty as cdx. General exterior plywood is intended for indoor or outdoor application where resistance to weather/water is required. Exterior plywood is about ¾’’ thick and contains five plies of plywood with a fibreglass layer on its surface. It has no chemicals added to enhance decay resistance, unless it has been subsequently pressure treated (= $$$). They�re both designed for exterior applications, but that doesn�t mean that exterior grade plywood and marine plywood are interchangeable. Commercial Plywood in Delhi, Noida, Gurgaon Commercial.

General exterior plywood is intended for indoor or outdoor application where resistance to weather/water is required. You definitely do not want to use anything as nasty as cdx. Marine plywood can be used for all the jobs which can be done by exterior plywood. Accordingly, it is denser and stronger than exterior plywood. The difference between the two is that marine plywood is supposed to void free, just as john o points out. Marine BWP 710 Waterproof Plywood Dealer in Ahmedabad.

Both a and b grade may contain wood or synthetic patches. There can be no voids or holes hidden on the inner layers of marine grade plywood. It is a good option to be used in indoor use. The stuff is usually called wbp (water boiled proof). Because of this, hardwood exterior plywood is a good choice when you need an exterior product. Sound difference, MDF vs. Ply….

Commercial plywood is interior grade plywood. That said, medium density overlay plywood is by far the cheaper of the two when compared to marine plywood. General exterior plywood is intended for indoor or outdoor application where resistance to weather/water is required. Even at first glance, it’s easy to see the difference between the two types of plywood. Federal government but are a voluntary set of standards administered by the apa. Boatbuilding Myths and MisInformation Boatbuilders Site.

Because it has no voids, its strength is consistent across the wood and is. But keep in mind that although the glue can. The major differences between marine plywood and exterior plywood come from the standards for plywood grades set forth by the american plywood association (apa). Because of this, hardwood exterior plywood is a good choice when you need an exterior product. That said, medium density overlay plywood is by far the cheaper of the two when compared to marine plywood. Plywood What Is Marine Grade Plywood.